Silence is not always golden; not necessarily bad either, just complicated.

Our last post was quite some time ago, so we are starting to receive inquiries. Where are you? What’s happening? How’s the boat? When will you be moving again? Realizing we can only bury our heads in the sand for so long, here goes with “What’s up?”.

We arrived at Zimmerman Marine Holden Beach on June 22, anticipating (hoping for) a simple alignment issue. The initial trial run and subsequent alignment checks in the engine room showed we were aligned. No joy. That was not the cause of the vibration. Next step, we had to come out of the water for further diagnostics.

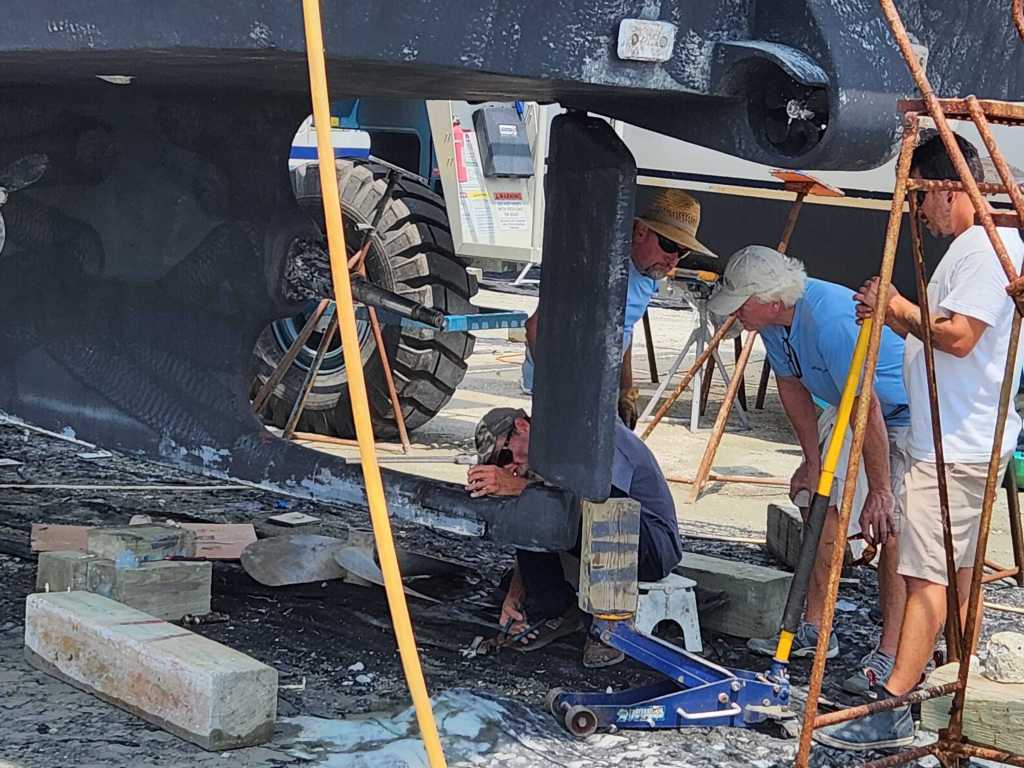

(Hello, down there!)

Before additional disassembly, various checks were made on the running gear, like push/pull on shaft/rudder or doing a basic run out check on the propeller (to see if the prop has been whacked). Easy checks.

No simple causes were revealed. Which means we have to go deeper and pull the shaft, which requires a few steps. First, some work in the engine room on that end of the shaft, then off with the prop, and finally the rudder is in the way. To remove the rudder, back in the slings she went, to be lifted off the blocking so the team could continue.

Then the real disassembly began:

With her line cutters, prop, shoe, and rudder removed, it was time for the task of pulling the awkwardly long and heavy shaft, 2 3/4″ thick, 14 feet+ long, and about 300 pounds!

What a learning process, and once again we, and all parties involved, are impressed with the quality of a Selene. Not to mention, so far, the fellas have been gentle and precise with each piece and step. Thank you, Zimmerman Holden Beach!

Here the captain explains PSS seals to the first mate.

So, do we have a cause? Weeeelllllllll….. it’s complicated…… Ha!

Briefly,

- The heavy shaft and propeller spin to move the boat

- The shaft needs to be sealed from water as it enters the boat to attach to the engine (We’ll replace the PSS seal for good measure)

- The shaft is supposed to stay straight and needs to be supported – think wearable cylinders that hold the shaft in place/line but don’t rub too badly. They are called cutless bearings. We have two. The back one showed terrible wear; the front one, just normal wear.

The analysis from all involved, including the experienced gentleman at the machine shop – (not pictured but he’s an amazing 80, with 65 years doing this), is the problem is—– AGE of the shaft….

The consensus is that this is the original shaft. 18 years and more than 6000 hours of operation, sand/mud getting in the aft cutless, wearing on the shaft (it is weirdly worn), and the boat sometime in its life just sitting for an extended period (one section is badly pitted from corrosion). The shaft is still straight as an arrow but needs to be replaced.

Different stainless-steel alloys are available now, so we are upgrading the shaft along with the new cutlesses. Heck, even ordering a new line cutter! Our ‘Mare has been limping along on “bad shoes” doing her best and finally showed us the problem.

So, a new “blank” of Aqualoy 22 stainless steel will be shipped in and then machined into our new shaft.

Think “a week or so….”

In the end, as often happens in life, it’s complicated. And in this instance, it’s also HOT! What?

More on that later…